Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

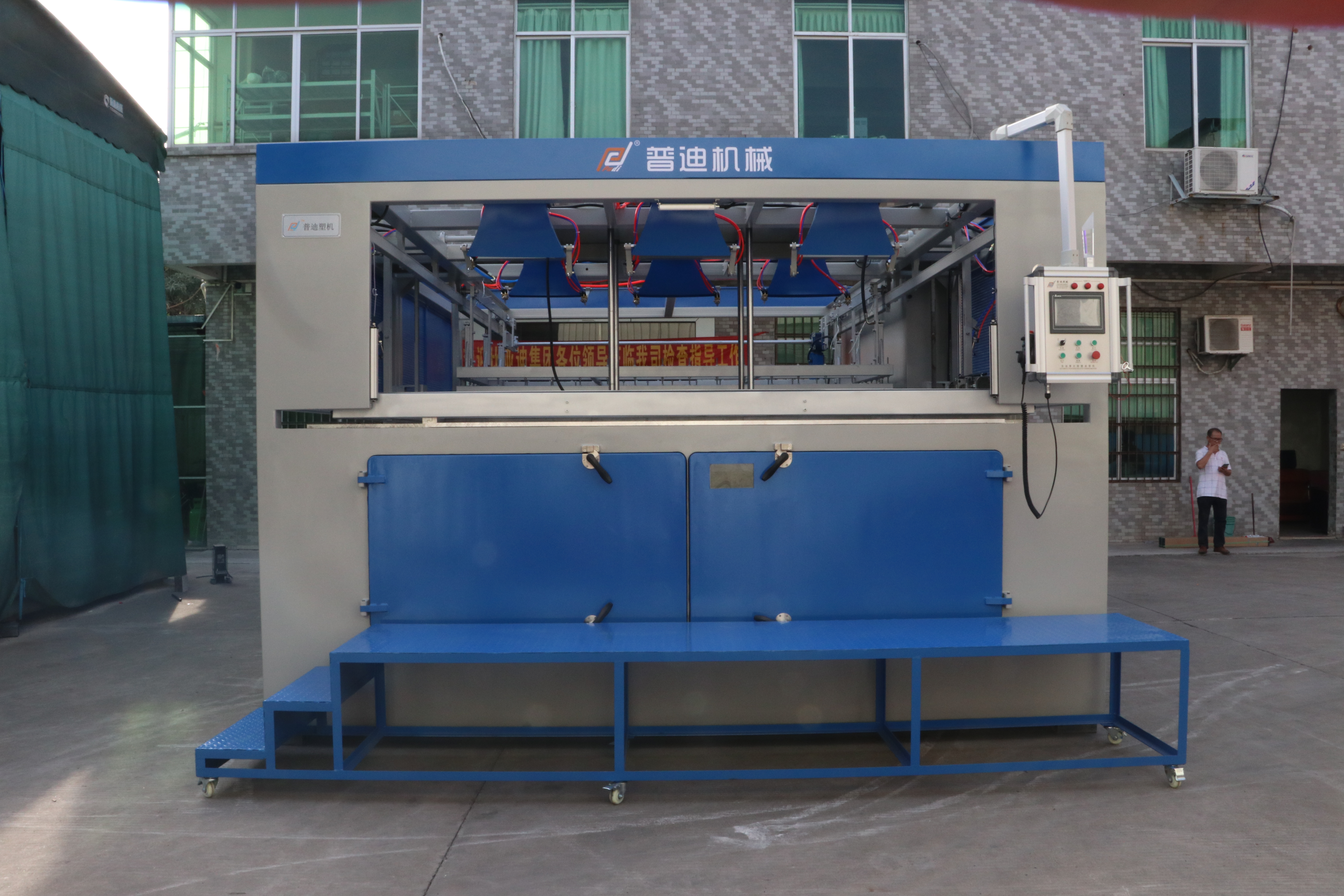

The new energy plastic battery box vacuum forming machine fit nowadays popular hot subject, green and environmental friendly. It can make biggest production with high efficiency and low energy-consuming, which can both save your cost and make you accept bigger orders. Are you looking for the machine that can make least input and most output? The machine is a great helper that can well guide you to make more money.

Green:

This machine is designed to help reduce energy consumption and waste, while providing superior quality and performance. It features advanced technology, including an automatic temperature control system and adjustable forming speed. The box produced is designed to keep your batteries safe and secure, and it is also water and dust resistant with its sleek and green design, the machine is easy to use and store. With its high production efficiency and low energy consumption, this machine is the perfect choice for green production.

Helpful for Manufacturers:

This machine is designed to help manufacturers create high-quality plastic battery boxes quickly and efficiently. Featuring a powerful vacuum forming system, it can quickly and accurately shape plastic into the desired form. With its easy-to-use interface and high speed, this machine is sure to be a helpful addition to any manufacturing facility. The high efficiency help manufacturers to accept bigger or more orders, which means that you can use the cheapest cost to earn the most price difference.

Product Parameter:

|

Maximum Wellhead Size |

2600mm*1600mm |

|

Forming Depth |

500 mm |

|

Applicable Material Thickness |

1-10mm |

|

Main Switch |

three-phase five-wire 380V±15V, 50Hz |

|

Heating Power |

Upper Furnace: 128kw; Lower Furnace: 128kw; |

|

Total Power |

280kw (subject to actual conditions, normal use is between 50-70%) |

|

Mold Forming Method |

Concave-convex molding (one-shot molding) |

|

Electric Furnace Power |

Frequency Conversion Motor Drive |

|

Die Power |

Servo Motor (both upper and lower mold tables are driven by servo) |

|

Cooling Form |

Powerful Fan |

|

Heating Unit |

fast medium-wave infrared heating tube, analog voltage regulation and temperature control |

|

Vacuum State |

Matching Large or Small Secondary Vacuum |

|

Upper Frame Structure |

It can be adjusted arbitrarily according to the different mold sizes |

|

Sheet Conveying |

Manual Placement |

|

Product Demoulding and Pick-up |

Air Pressure Blowback Demoulding |

|

Other Functions |

Bubble Blowing, Anti-sag, Large and Small Vacuum |

|

Adaptable Processing Materials |

PP. PC. PE. PVC. ABS. PS and other thermoplastic sheets |

|

Machine Dimension |

3800mm*4600mm*3200mm (excluding the upper mold) |